Srons Engineers are manufacturers and exporters of Double Corrosion Protection Anchors / DCP Bolts in India, Punjab Ludhiana.

DCP BOLTS - DOUBLE CORROSION PROTECTION ANCHORS

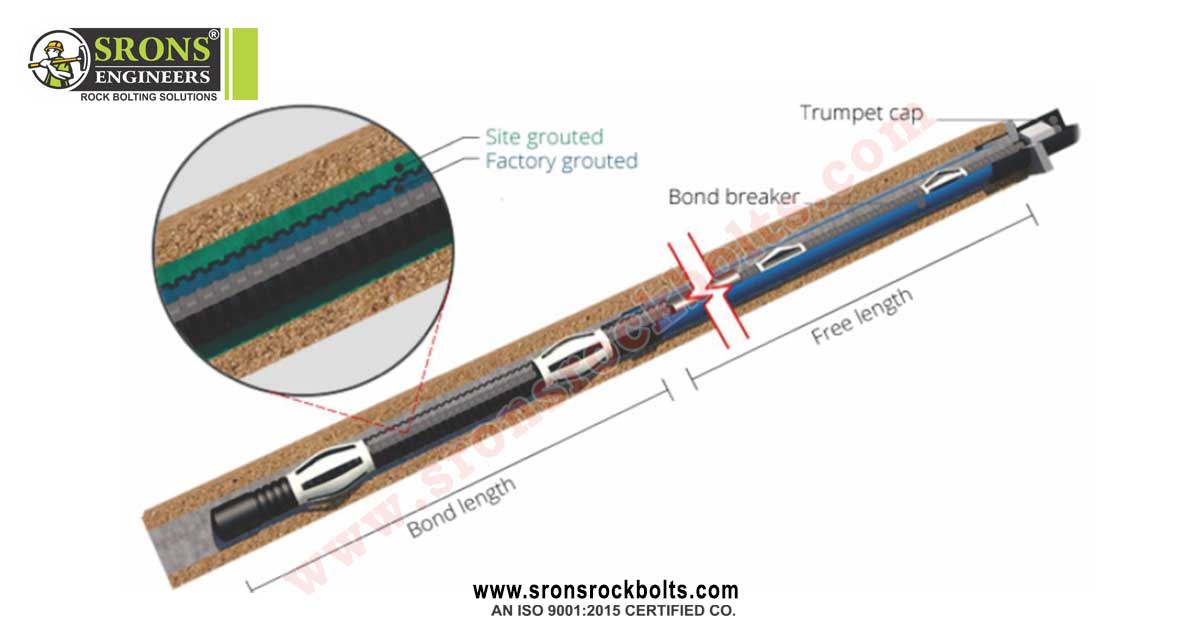

Double corrosion anchor required which has following properties/components:

- Anchor Length: Total Anchor length -Free length + Fixed Length + Stressing Tail Length- Fixed Length: To be designed

- Free length: To be designed

- Stressing Tail Length: To be designed

- Anchor Main Bar Dia: 32mm

- Bar Grade: 950/1050

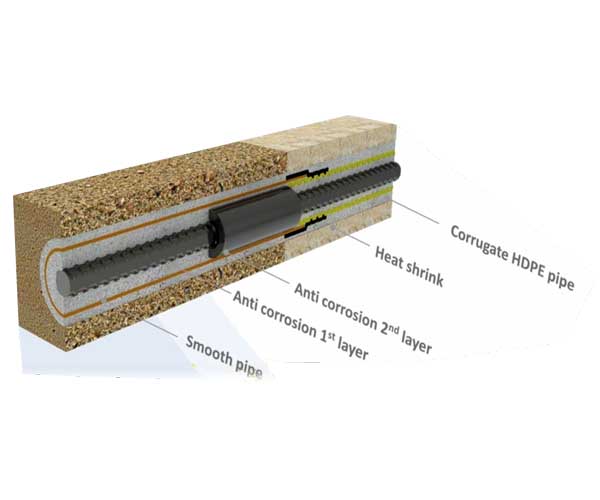

- Corrosion Requirements: Double Corrosion Protection

SRONS Solutions: We manufacture & Supply Double corrosion anchor required which has following properties/components:

| Material | Fixed Length in RM | Free Length in RM | Stressing Tail Length in RM |

| 32mm FT bar Anchor incl Stressing Length | To be designed | To be designed | To be designed |

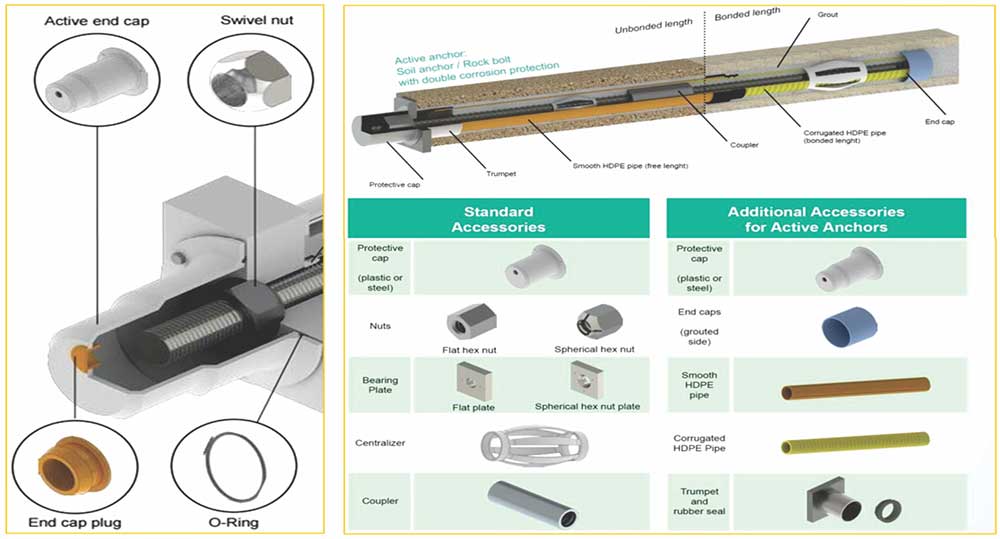

| Materials |

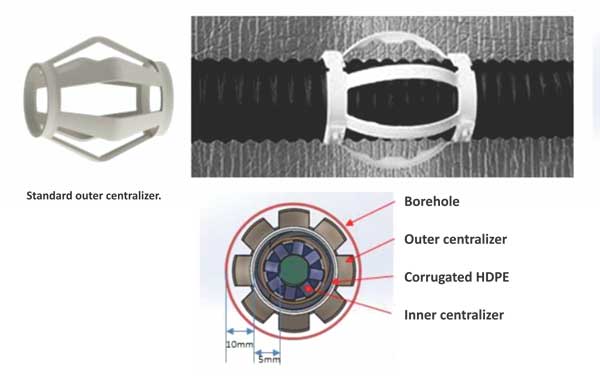

| Inner Corrugated HDPE/PVC Corrugated Tube |

| Outer Debonding Smooth Tube |

| Inner Centralizer Fixed Length |

| Inner Centralizer Free Length |

| Outer Centralizer Fixed Length |

| Outer Centralizer Free Length |

| Coupler for 32mm |

| Anchor End Cap |

| Spherical Hex Nut |

| Protective Cap on Anchor Head |

| Grout Tube |

| Steel Anchor Plate |

| 32mm Dia FT Bar in Grade 950/105 |

| Inner Grouting |

Product Technical Specifications:

Fully Threaded Bar |

||

| Properties | Unit Of measurement | Value |

| Nominal Outer Diameter | mm | 32 |

| Cross Sectional Area | mm2 | 804 |

| Nominal Mass per meter | Kg | 6.53 |

| Yield Strength | Mpa | 950 |

| Ultimate Strength | Mpa | 1050 |

| Characteristic breaking load | kN | 845 |

| Max. initial stressing force | kN | 676 |

| Max. overstressing force | kN | 722 |

Coupler |

||

| Properties | Unit Of measurement | Value |

| Nominal Outer Diameter | mm | 60 |

| Length | Mm | 160 |

| Inner Diameter | Mm | 32.5 |

| Material Grade | Mpa | 950/1050 |

| Nominal Wt./Pc | Kg | 2.45 |

Dome Nut |

||

| Properties | Unit Of measurement | Value |

| Nominal Outer Diameter | mm | 60 |

| Length | Mm | 50 |

| Inner Diameter | Mm | 58 |

| Material Grade | Mpa | 950/1050 |

| Nominal Wt./Pc | Kg | 1.40 |

Plate |

||

| Properties | Unit Of measurement | Value |

| Width | mm | 180 |

| Length | Mm | 180 |

| Thickness | Mm | 40 |

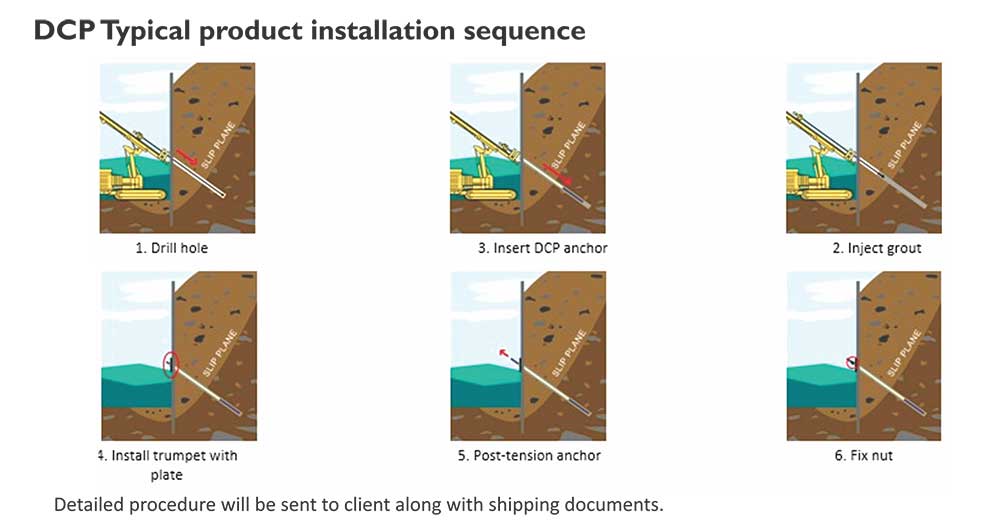

Installation Guidelines:

(1) Anchors Reception

- Check all anchors and components for possible transportation damage.- Do not use anchors that have been bent or that have any surface damage.

- Do not use bars as ground for welding, do not allow hot slag to touch the bars, and do not weld to bars.

- Handle anchors with care using nylon lifting slings. The bars must not be dropped, thrown or dragged.

- Upon unloading, protect the bars from dirt and mechanical damage.

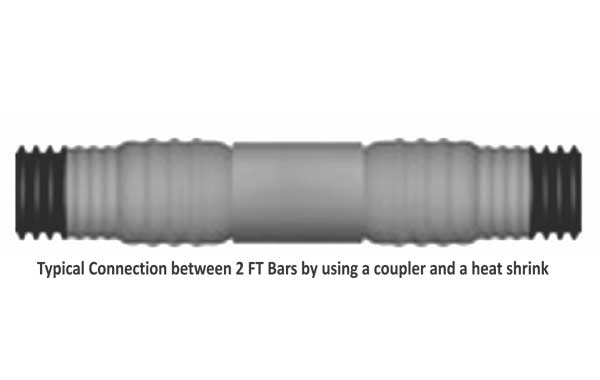

(2) DCP couplers in the bond and free lengths.

- Grease both bar ends thoroughly.- Install coupler, bar ends must be centered inside coupler.

- Torque bar against each other

- Grease coupler thoroughly.

- Install heat-shrink sleeve.

- Important: do not burn the heat shrink sleeve nor the plastic sheathing.

(3) Grout tube and outer centralize assembly.

- Install outer centralizers within the bond length using adhesive tape and / or wire at the required spacing.- If applicable, install grout tube using adhesive tape. The grout tube must start 50 to 100mm from the bottom of the anchor and extend at least 1 meter above the anchor head.

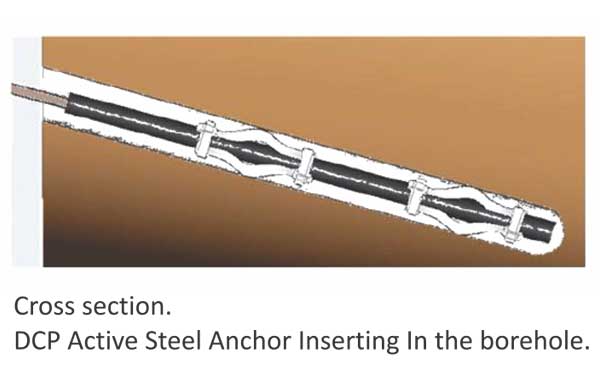

(4) Inserting the anchor into the borehole

- If necessary, water-test the borehole according to the project specifications.- Using a lifting eye or another equivalent attachment, lift the anchor from the achor head end, important do not drag.

- Insert the anchor into the borehole gradually making sure that it does not get damaged.

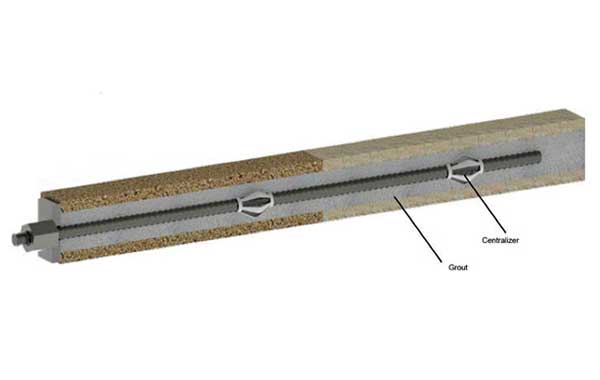

(5) Grouting of the anchor, installation of the trumpet & anchor nut

- Ensure that the anchor is centered in the borehole.- Leave enough bar protruding behind the plate for the anchor nut and the stressing coupler (typically 500mm).

- Also ensure that there is sufficient bare bar inside the sealing tube of the trumpet to allow for free movement during tensioning of the anchor (typically 150mm).

- Grout the entire anchor is one stage according to the product specifications.

- While the grout is still wet, wash out 1.0 meter below the location of the anchor plate.

- Install the trumpet pre-filled with anti-corrosion compound over the bar, ensure the sealing tube is correctly engaged over the smooth pipe (bondbreaker) and the sealing ring of the corrugated pipe.

- Fasten anchor nut tight against the bearing plate.

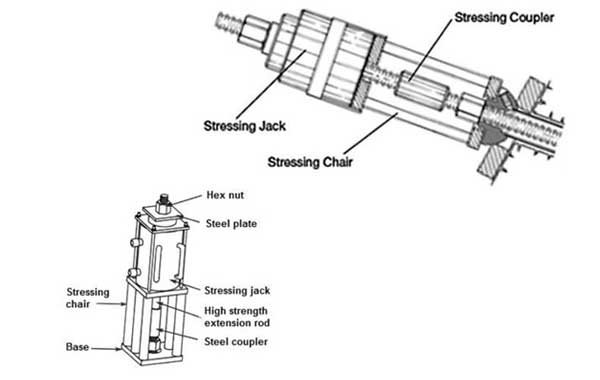

(6) Testing and Stressing

- Once the grout reached its required compressive strength, stress the bar according to project specifactions and contract drawings.

(7) Protective caps installation.

- Pre-fill the cap with anti-corrosion compound.- Install it over the anchor nut with corresponding seal (O-ring).

- Bolt the cap onto the trumpet (3 screws).

- Full-fill any residual gap with anit-corrosion compound through the injection hole.

- Seal the injection hole with the end-cap plug.