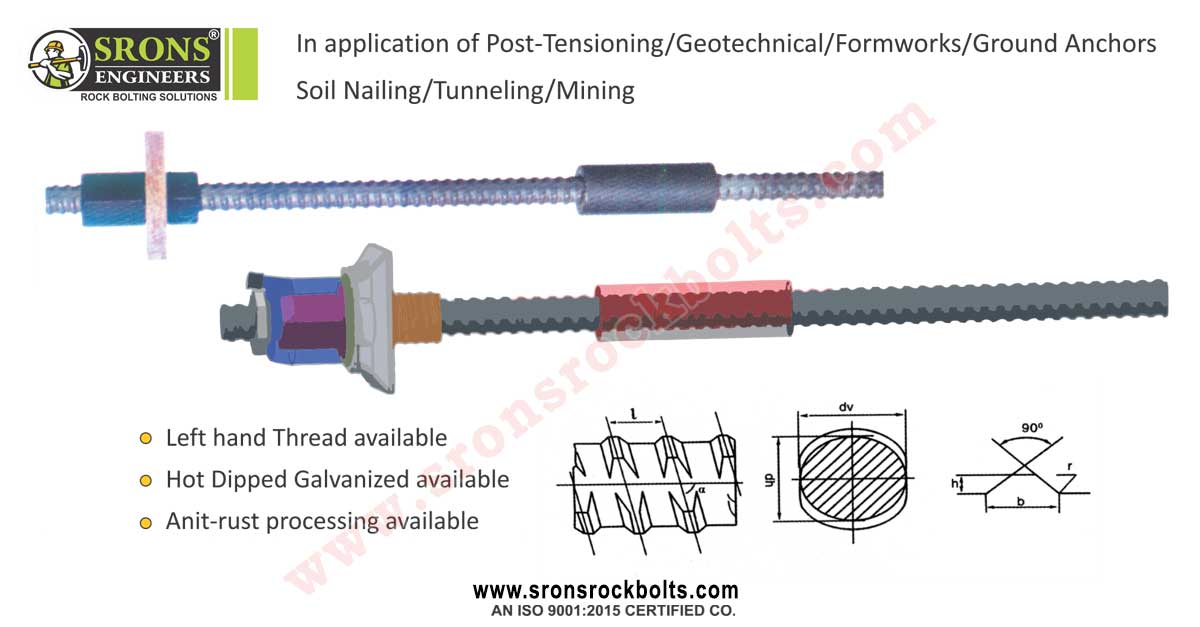

High Strength Bar / Post-Tensioning Bar

| MM | MM | MM | MM | MM | R/MM | |||||||

| DH | SV | H | B | I | ||||||||

| 15 | 15 | ± 0.3 | 15.0 | +0.4-0.8 | 1.2 | ± 0.3 | 4.0 | 10.0 | ± 0.2 | 1.0 | 80deg 42' | |

| 20 | 20 | 20.0 | +0.4-0.8 | 1.3 | 4.8 | 10.0 | ± 0.2 | 1.2 | 80deg 42' | |||

| 25 | 25 | ± 0.4 | 25.0 | +0.4-0.8 | 1.6 | ± 0.3 | 6.0 | 12.0 | 1.5 | 81deg 19' | ||

| 32 | 32 | ± 0.5 | 32.0 | +0.4-1.2 | 2.0 | ± 0.4 | 7.0 | 16.0 | ± 0.3 | 2.0 | 80deg 40' | |

| 36 | 36 | ± 0.5 | 36.0 | +0.4-1.2 | 2.2 | ± 0.4 | 8.0 | ± 0.5 | 18.0 | 2.5 | 81deg 50' | |

| 40 | 40 | 40.0 | +0.4-1.2 | 2.5 | ± 0.5 | 8.0 | 20.0 | 2.5 | 80deg 29' | |||

| 50 | 50 | ± 0.5 | 50.0 | +0.4-1.2 | 3.0 | - 0.5 | 9.0 | 24.0 | ± 0.4 | 2.5 | 81deg 19' | |

| 75 | 75 | 75 | - | - | - | - | - | - | - | |||

Fully Threaded Bar Systems

| Nominal Diameter |

Cross Section Area |

Linear Weight |

Grade 525/575 | Grade 670/800 | Grade 835/1035 | Grade 935/1085 | ||||

| mm | mm² | kg/m | Yield Load (kN) |

Ultimate Load (kN) |

Yield Load (kN) |

Ultimate Load (kN) |

Yield Load (kN) |

Ultimate Load (kN) |

Yield Load (kN) |

Ultimate Load (kN) |

| 25 | 491 | 4.1 | 270 | 375 | 330 | 390 | 405 | 500 | 450 | 500 |

| 28 | 616 | 4.85 | 308 | 339 | 390 | 470 | N/A | N/A | 500 | 620 |

| 32 | 804+ | 6.50 | 300 | 400 | 400 | 500 | 510 | 720 | 740 | 800 |

| 36 | 1018 | 8.41 | 560 | 780 | N/A | N/A | 840 | 1040 | 940 | 1090 |

| 40 | 1257 | 10.34 | 690 | 960 | N/A | N/A | 1040 | 1290 | 1160 | 1350 |

| 43 | 1450 | 11.43 | 726 | 799 | 970 | 1160 | 1300 | 1650 | N/A | N/A |

| 50 | 1964 | 16.28 | 1080 | 1500 | N/A | N/A | 1600 | 2010 | 1820 | 2110 |

| 57.5 | 2550 | 20.44 | 1400 | 1800 | 1740 | 2077 | 2150 | 2670 | N/A | N/A |

| 63.5 | 3165 | 24.23 | 1700 | 222 | 2120 | 2530 | 2700 | 3300 | N/A | N/A |

| 75 | 4418 | 35.9 | 2100 | 2350 | 2870 | 3500 | 3600 | 4500 | N/A | N/A |

Product Features

- High Tensile fully threaded bars available in three grades for passive and active pre-tensioned) anchors.- Higher grades & higher size are also available on request.

- Diameter range 25mm to 75mm

- Continuous cold rolled & hot rolled available thread.

- Minimum Elongation

* Gr 525/575 6%

* Gr 670/800 6%

* Gr 835/1085 6%

- Available with either left hand or right hand threads.

Benefits

- High grade steel effectively reduces the diameter of the bar allowing for easier handling and a smaller bore hole.- Continuous thread makes connections, possible at any point and increasing bonding.

- Coarse thread and surface hardening allow for rough handling.

- Pre-stressing possible for active anchors (available for grade 835 / 1035)

ABOUT OUR RANGE

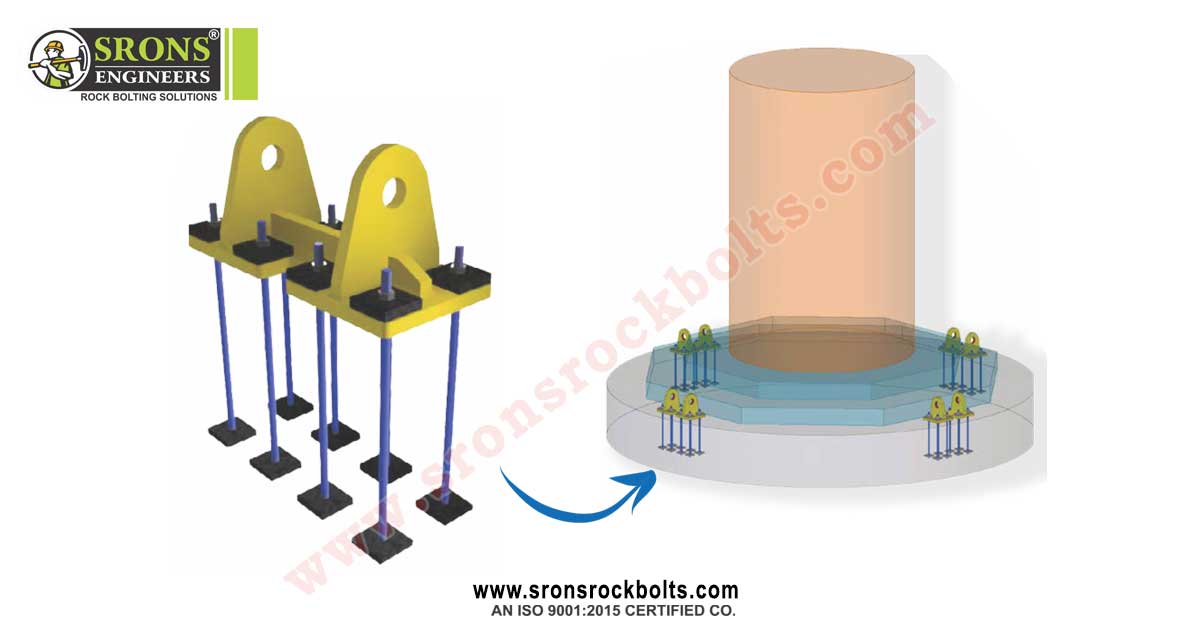

Post-Tensioning bars are used for permanent works such as connecting various segments of bridge structures, shear keys for seismic resistance at the connection of segments or girders and piers, and reinforcement of piers that are subject to horizontal pre-stressing forces.They are also used for temporary works such as anchoring of temporary steel frame supports, lifting bars for segment launching trusses, and stitching bridge segments.

These bars need to have sufficient strength properties to carry the heavy loads of structures and pre-loading to balance the external loads structures are subjected to at a later stage.

Our post-tensioning range features both fully-threaded bars and smooth bars, with a full range of accessories.

The services of a fully dedicated design team are available to provide engineering support to our customers.

TYPICAL APPLICATIONS

• Post-tensioning of concrete structures.• Temporary bracing/Temporary post-tensioning.

• Heavy lifting.

• Seismic restrainer system.

• Hold down for steel structure, wind turbine.

• Structural steel frame ties.

• Bridge segment connections.

• Bridge segment continuity tendons.

• Pre-stressed concrete.

• Pile-testing.

CORROSION PROTECTION

Various corrosion protection are available depending on whether tendon is temporary permanent, bounded, unbounded, with or without free length. Protection is usually achieved with a combination of heat shrink, grease, paint and/or grout.The smooth bars for shear key applications are normally supplied in a HDPE tube injected with grease and specially designed accessories.

Smooth Bar Range

Smooth Bar Range

Product Features

- Diameter range from 28mm to 100mm.- Three steel grades available.

• Gr 825/1035

• Gr 925/1075

• Gr 1025/1210

- Rolled threads (obtained with cold plastic deformation of the metal between two dies) optimized for fatigue performance.

- Thread profile is ISO metric thread according to ISO 262 - NFE 03014 and 03053.

Product Benefits

- High Impact resistance.- Smaller pitch allows finer adjustment and brings less draw-in loss.

- Full range of accessories for specific applications.

- High fatigue performance.

Special Application

Shear Key & Hold Down Bars Application - Shear key and hold down bars are a special application of PT smooth bar systems where assembly acts as a permanent seismic restrainer for the connection of elevated metro/roads precast segments.- Shear key bar systems and hold down bar systems are available with their full range of accessories for grade 1025/1210 and come in two diameters: 37mm (thread M39) and 43mm (thread M45).

Load Table

| Thread Size |

Critical Cross Section Area |

Nominal Diameter |

Linear Weight |

Grade 825/1035 | Grade 925/1075 | Grade 1025/1210 | |||

| mm² | mm | (kg/m) | Yield Load (kN) |

Ultimate Load (kN) |

Yield Load (kN) |

Ultimate Load (kN) |

Yield Load (kN) |

Ultimate Load (kN) |

|

| M30 | 561 | 28 | 4.83 | 468 | 578 | 522 | 606 | 589 | 673 |

| M33 | 694 | 31 | 5.92 | 579 | 715 | 645 | 750 | 729 | 833 |

| M36 | 817 | 34 | 7.13 | 682 | 842 | 760 | 882 | 858 | 980 |

| M39 | 976 | 37 | 8.44 | 815 | 1005 | 908 | 1054 | 1025 | 1171 |

| M42 | 1121 | 40 | 9.86 | 936 | 1155 | 1043 | 1211 | 1177 | 1345 |

| M45 | 1307 | 43 | 11.40 | 1091 | 1346 | 1216 | 1412 | 1372 | 1568 |

| M48 | 1474 | 45 | 12.48 | 1230 | 1518 | 1371 | 1592 | 1548 | 1769 |

| M52 | 1758 | 49 | 14.80 | 1468 | 1811 | 1635 | 1899 | 1846 | 2110 |

| M56 | 2031 | 53 | 17.32 | 1695 | 2092 | 1889 | 2193 | 2133 | 2437 |

| M60 | 2363 | 57 | 20.03 | 1972 | 2434 | 2198 | 2552 | 2481 | 2836 |

| M64 | 2676 | 61 | 22.94 | 2234 | 2756 | 2489 | 2890 | 2810 | 3211 |

| M68 | 3056 | 65 | 26.04 | 2551 | 3148 | 2842 | 3300 | 3209 | 3667 |

| M72 | 3460 | 69 | 29.35 | 2889 | 3564 | 3218 | 3737 | 3633 | 4152 |

| M78 | 4114 | 75 | 34.67 | 3435 | 4237 | 3826 | 4443 | 4320 | 4937 |

| M83 | 4702 | 80 | 39.45 | 3926 | 4843 | 4373 | 5078 | 4937 | 5642 |

| M88 | 5329 | 85 | 44.54 | 4450 | 5489 | 4956 | 5755 | 5595 | 6395 |

| M93 | 5996 | 90 | 49.93 | 5006 | 6176 | 5576 | 6476 | 6296 | 7195 |

| M98 | 6702 | 95 | 55.63 | 5596 | 6903 | 6233 | 7238 | 7037 | 8042 |

| M103 | 7447 | 100 | 61.64 | 6218 | 7670 | 6926 | 8043 | 7819 | 8936 |

Srons Smooth Bar System in Action

Srons Smooth Bar System in Action

Accessory for Thread Bar

Full Hex Nut & Spherical Hex Nut

| D MM | 500 & 670 Grade | 830 & 930 Grade | |||

| Hex (mm) | Length (mm) | Hex (mm) | Length (mm) | Weight | |

| 25 | 46 | 46 | 50 | 60 | |

| 28 | 46 | 50 | 50 | 60 | |

| 32 | 50 | 60 | 65 | 70 | |

| 36 | 55 | 70 | 65 | 80 | |

| 40 | 60 | 90 | 70 | 100 | |

| 43 | 64 | 95 | 74 | 110 | |

| 50 | 70 | 100 | 80 | 120 | |

| 57.50 | 80 | 120 | |||

| 63.50 | 100 | 130 | |||

| 75.00 | 120 | 150 | |||

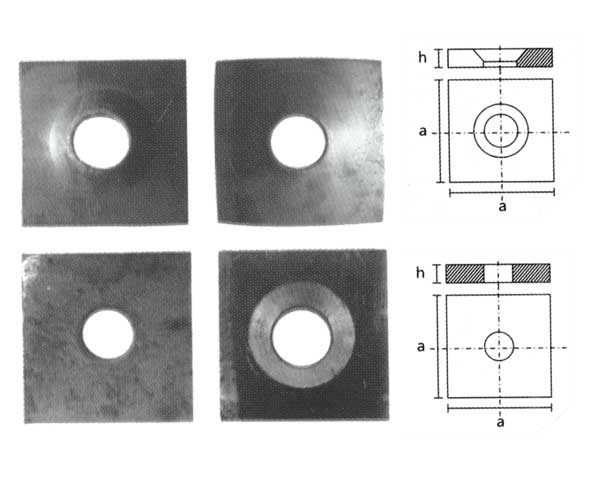

Nail Bearing Plate

| D MM | Square (mm) | Hole (mm) | Thickness (mm) | Material | KG |

| 25 | 150200 | 35 | 8,10,12 | ||

| 28 | 150200 | 35 | 8,10,12 | ||

| 32 | 200250 | 40 | 8,10,12,20 | ||

| 36 | 200250 | 50 | 12,20,25 | E250 | |

| 40 | 250 | 60 | 20,30,40 | E350 | |

| 43 | 250 | 60 | 20,30,40 | MS | |

| 57.50 | 300 | 75 | 40,50 | ||

| 63.50 | 300 | 80 | 40,50 | ||

| 75.00 | 400 | 100 | 50,75 |

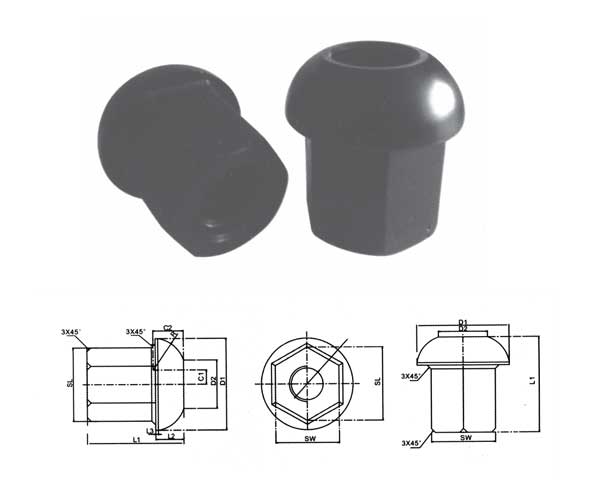

Domed Nut

| Dome Nut | 500 & 670 Grade | 835 & 935 Grade | ||||

| Dia | Hex (mm) | Length (mm) | Dome Dia (mm) | Hex (mm) | Length (mm) | Dome Dia (mm) |

| 25 | 46 | 54 | 54 | 50 | 60 | 60 |

| 28 | 46 | 54 | 54 | 50 | 60 | 60 |

| 32 | 50 | 60 | 60 | 60 | 70 | 70 |

| 36 | 60 | 70 | 70 | 65 | 90 | 90 |

| 40 | 65 | 90 | 90 | 70 | 100 | 100 |

| 43 | 70 | 100 | 100 | 70 | 100 | 100 |

| 50 | 70 | 100 | 100 | 85 | 140 | 120 |

| 57.50 | 85 | 120 | 120 | 100 | 150 | 150 |

| 63.50 | 85 | 120 | 120 | 100 | 150 | 150 |

| 75 | 110 | 150 | 150 | 110 | 150 | 150 |

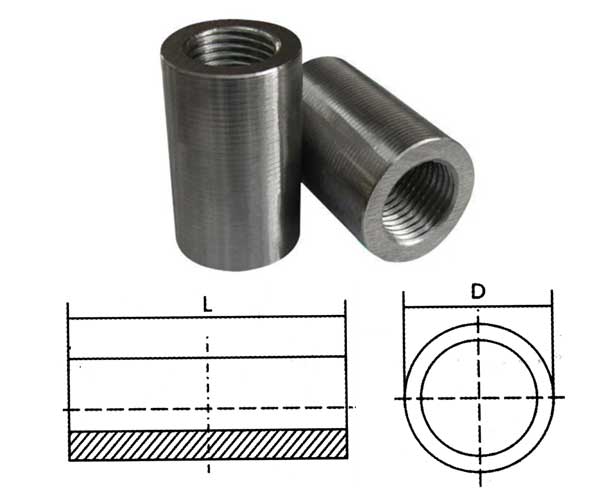

Couplers

| Coupler | 500 & 670 Grade | 835 & 935 Grade | ||

| Dia | OD (mm) | Length (mm) | OD (mm) | Length (mm) |

| 25 | 46 | 160 | 52 | 132 |

| 28 | 46 | 160 | 52 | 145 |

| 32 | 50 | 160 | 60 | 168 |

| 36 | 60 | 170 | 70 | 200 |

| 40 | 65 | 175 | 75 | 220 |

| 43 | 70 | 200 | 80 | 230 |

| 50 | 70 | 200 | 90 | 290 |

| 57.50 | 85 | 220 | 100 | 300 |

| 63.50 | 85 | 220 | 100 | 300 |

| 75 | 110 | 250 | 115 | 320 |

Marine Tie Rods

Marine Tie Rods