Rebars Fully Threaded Bolts

SN ROCK BOLT SYSTEM

Grouted rockbolts have been commonly used world-wide in mining and civil engineering applications. The most commonly used grouted rockbolt is the fully grouted rebar or threaded bar made of steel. Cement or resin are used as grouting agent. The rebar used with resin creates a system commonly used for tensioned rockbolt but the rebar or the threaded bar with cement grout can also be used for untensioned bolts.

FE500 Grade C - EN 10080

| Steel Quality Designation: | FE500 Grade C - EN 10080 | ||

| Steel Diameter: | 25mm | 32 mm | 40 mm |

| Yield Load, Steel: | >500MPa | >500MPa | >500MPa |

| Ultimate Load, Steel: | >550Mpa | >550Mpa | >550Mpa |

| Weight of Bolt (Without plate and nut) : | 3.85 kg/mt | 6.31 kg/mt | 10.00 kg/mt |

| Bolts Length : | Any Length Required | ||

| Thread at one end x 100mm | M24 | M30 | M38 |

Hexagon Nut Class 8 ISO Metric Thread

| NUT | Hexagon Nut Class 8 ISO Metric Thread | ||

| Steel Quality Designation : | UNI 3740 ISO 898-2 | ||

| Dimension : | 36 x 19mm | 46 x 32mm | 55 x 40mm |

| Coarse Thread : | 3 | 3.5 | 4.5 |

| Weight : | 0.11 Kg | 0.26 Kg | 0.55 Kg |

E250 - EN 10025-2

| Steel Quality Designation : | E250 - EN 10025-2 | ||

| Rockbolts Dia 25mm |

Rockbolts Dia 32mm |

Rockbolts Dia 40mm |

|

| Dimension : | 150x150x8mm | 200x200x10mm | 200x200x12mm |

| Shape - Hole | Flat - Central Hole Dia 28mm |

Flat - Central Hole Dia 35mm |

Flat - Central Hole Dia 43mm |

| Weight : | 1.360 kg | 3.10 kg | 3.60 kg |

| Optional : | 20mm Hole for injection tube | ||

Rebars Fully Threaded Bolts

Specifications

| Dimension | Material (1) | Thread Length | Weight | Borehole | |

| Diameter, mm | Depth (2) | ||||

| M20x2,5 | FE500D | M20x150mm | 2,47kg/m | Ø45-48 | L+150mm |

| M22x2,5 | FE500D | M22x150mm | 2,98kg/m | Ø45-48 | L+150mm |

| M25x3.0 | FE500D | M24X150mm | 3.90kg/m | Ø64-68 | L+150mm |

| M32x3,5 | FE500D | M32x200mm | 6,43kg/m | Ø64-68 | L+150mm |

Mechanical Properties

| Dimension | Tension Area as Thread-Shank |

Yield Stress Reh | Tensile Stress Rm | Ductility Agt |

| M20x2,5 | 245-314 N/mm² | Min. 500 N/mm2 | Min. 565 N/mm2 | Min. 8% |

| M22x2,5 | 303-380 N/mm² | Min. 500 N/mm² | Min. 565 N/mm2 | Min. 7,5% |

| M25X3.0 | Min. 500 N/mm2 | Min. 565 N/mm2 | Min. 8% | |

| M32x3,5 | 694-804 N/mm² | Min. 500 N/mm2 | Min. 565 N/mm2 | Min. 8% |

Minimum Load Capacity

| Dimension | End anchored (³) | Fully grouted | Torque Nm | Pre - Tension kN | ||

| Yield kN | Failure kN | Yield kN | Failure kN | |||

| M20x2,5 | 123 | 147 | 157 | 186 | 150-250 | 40-60 |

| M22x2,5 | 191 | 239 | 239 | 300 | 150-250 | 40-60 |

| M25x3.0 | 240 | 320 | 270 | 375 | 200-300 | 40-60 |

| M32x3,5 | 347 | 416 | 402 | 482 | 200-300 | 40-60 |

2) L=bolt length

3) Poor and soft rock quality may give lower values.

Test on site under actual conditons to correctly establish representative values.

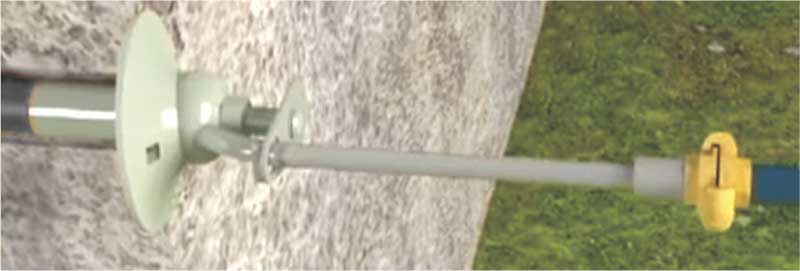

INSTALLATION, EQUIPMENT

Installation takes place in two steps:1) Place the bolt in the hole and tension it by applying correct torque on the nut.

2) Grout injection for permanent anchoring and protection.

Immediate support by placement and tensioning at the tunnel face.

The grouting tool gets attached to the bolt head before start of the mortar pump.

(Two alternative types of grouting tools are available)

(Two alternative types of grouting tools are available)

Mortar gets pumped through the hole in the grouting head to fill the annular space from bottom of hole out to the spherical bearing plate.

In the bearing plate you can see the hole indicating completely filled borehole.